DESIGNATED MEETING ROOM: 227

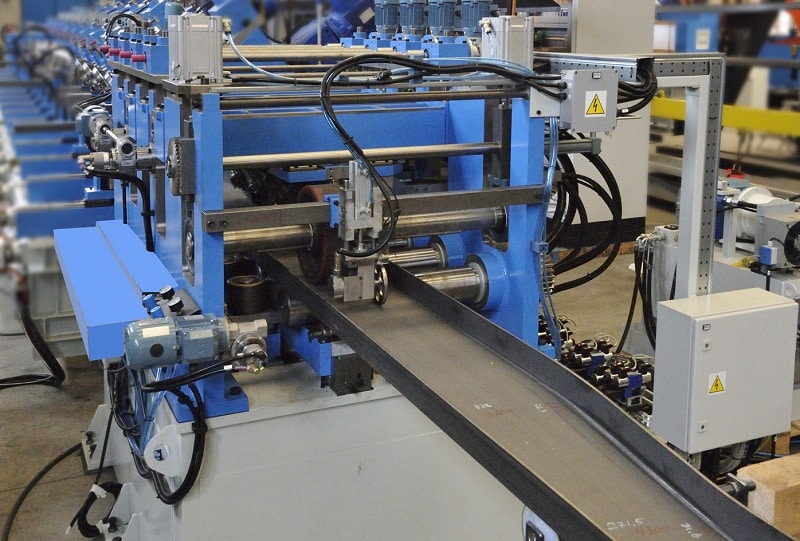

“Material and How it Affects Metal Building Products in the Roll Forming Process” Presented by Brian Rogers

This presentation will focus on how material changes can make a difference in your products. When material is changed, it can make slight differences that may change your part. Adjustments may be necessary to keep the desired outcome. Die tonnage, roll design, and roll former overall strength issues will be included in the discussion.

“Creative Options for Punching/Shearing/Cutoff Challenges in the Metal Building Industry” Presented by Paul Williams

- This session will help you understand the different types of punching and cutoff systems required for automating roll forming lines for the metal construction industry.

Areas to be covered include:

- Punching systems for purlins, studs, joists, corner beads, vertical commercial siding.

- Stationary punching systems with servo-feeds.

- Flying punching systems with electronic measuring.

- High-speed rotary punching units.

- Cut off systems for roof panels, siding panels, purlins, studs, joists, etc..

- Measurement and acceleration methods.

- What type of press is best for each application?.

- Pre-shear and post-cutoff systems.

“Advanced Roll Forming of Steel Framing Components” Presented by Brian Rodgers

This presentation will provide insight into the latest advancements in roll forming system technology for the Steel Framing Industry. Discussions will focus on automated equipment change-over for material thickness, cross sectional variations, punched opening locations, and part lengths. Handling of the finished product in high-speed operations will be discussed. Also addressed, will be the level of operator training required. The advantages of programmable rotary punching and cutoff systems will be presented. Included, will be specific examples of these technologies being utilized in the manufacture of steel framing products.

“Automation and Material Handling for Roll Formed Products – Emphasizing Operator Safety, Labor Reduction & High-Speed Production” Presented by Chuck Summerhill

The need for material handling and automated packaging equipment can be justified from safety, labor reduction, or for high-speed production requirements. Automated packaging can solve all three requirements. This presentation will educate companies on how to identify which categories and prioritize their material handling requirements. The presentation will then explore the current solutions that are feasible within an example company’s current budget and detail the solutions payback.

This workshop is located in meeting room #227 and requires pre-registration, an additional fee and includes your exhibit hall pass.

Learn more about our NEW Value Pass options for the BEST DEAL for adding workshops to your agenda!

Speakers:

Brian Rodgers, Sr.

Application Engineer, FormTek, Inc.

Brian began his experience as a roll form operator and realized he had a great interest in roll form methodology and entered an apprenticeship program to learn troubleshooting and department leadership. During the apprenticeship, his duties included new tooling tryout, troubleshooting of roll form processes, set up, and leadership. Brian became a supervisor with duties including scheduling and troubleshooting of 22 roll mill lines, 25 operators, and set up personnel. He then expanded into tool engineering where he focused on new tooling and continuous improvement projects. Additional duties included new tooling and equipment buy offs. He joined Formtek, Inc. to begin a new chapter in his career as a Senior Applications Engineer. Responsibilities include helping solve customer request using the roll forming process. Brian is a member of and a Past Chair of FMA’s Roll Forming Council.

Paul Williams

Director of Sales, Hill Engineering

Paul Williams is the Vice President of Business Development for Formtek & Formtek Regional Sales Manager – West. Paul has over 39 years’ experience in the tool and die and rollforming industries as a toolmaker, field service technician, die design engineering, sales application engineering, product line manager, regional sales manager and director of sales. Paul received his schooling from the Tooling and Manufacturing Association in tool and die making and engineering, and has a Bachelor of Science in Business Administration. Paul has been with Hill Engineering since 1988 and has been a speaker and conference chairman for FMA, PMA and SME conferences, and has authored technical articles in leading industry publications. Paul served on the Fabricators and Manufactures Association ‘s Board of Directors as an Associate Director during 2013-2014, is a current member and past chairman of FMA’s Roll forming and Technology Council.

Chuck Summerhill

Technical Sales/Engineer, TEKFAB

Chuck has worked in the roll forming industry for 34 years with Ardcor and Roll-Kraft, serving in numerous positions in engineering and operations management. In the fall of 2014, Chuck began working with TEKFAB Inc., Albany, Oregon, and serves as a Technical Sales Engineer for roll forming systems, presses and material handling equipment. He works out of the sales/engineering office in Cleveland, Ohio. Chuck is a member of and a Past Chairman of FMA’s Roll Forming Council.