DESIGNATED MEETING ROOM: 227

“Considerations for Metal Building Roll Formers” Presented by Matt Werner and Shawn Huffman

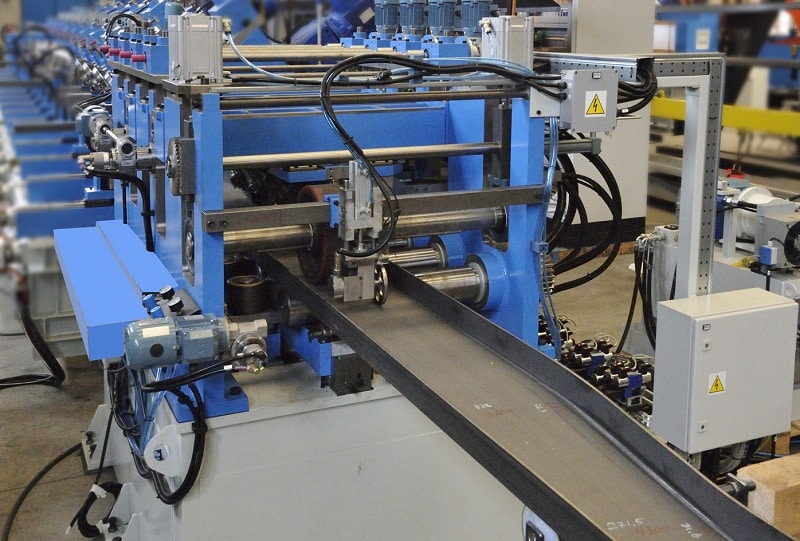

This presentation will challenge participants to think about panel, purlin, and trim roll forming in a production environment. How does technology apply to return on investment? What is the balance between technology and resources? Does automation help the bottom line? Understand equipment used in the production of metal building components, what components to look for when investing in equipment, and technology and efficiency as it relates to productivity.

“Utilizing Existing Capital Equipment and Tooling” Presented by Brian Rogers, Sr.

With today’s changing products and the pressure of custom products, a company needs the ability to be flexible. Being flexible in the roll forming industry is nothing new. Today there are roll forming machines that are 50+ years old meeting today’s demands. Many of these machines have had face lifts and tweaks at a fraction of the cost of new equipment. New tooling, controls, rebuilds, and focus have been the keys to the success. This class will look at utilizing your equipment and will help with the points of evaluation needed to use older equipment. Whether using some or all existing equipment, companies can develop economical solutions for today’s demands.

“Improve Profitability & Competitiveness through Computer Integrated Manufacturing” Presented by Andy Allman

Learn how to eliminate production mistakes, minimize scrap and improve your responsiveness to customer needs. Integrated roll forming and trim shop machine controls support downloading of production schedules, ensure the correct coil is used for every order, and can track everything that happens at each machine. Find out the true production capacity of your machines and who your best operators are. Use OEE to monitor productivity and Pareto analysis to help prioritize your continuous improvement efforts. As competition becomes more intense, you cannot afford to be stuck with a manual production control system.

“Proper Roll Form Tooling Setup and Troubleshooting” Presented by Steve Ebel

This presentation will show how to set up roll form tooling and document the setup. The session will also cover inspection of the roll former and how to maintain the machine face alignment or calibrate the machine to achieve the best possible setup of roll form tooling. Build standard ideas for roll form tooling manufacture as well as useful hints on troubleshooting the tooling and setup will also be shared.

This workshop is located in meeting room #227 and requires pre-registration, an additional fee and includes your exhibit hall pass.

Learn more about our NEW Value Pass options for the BEST DEAL for adding workshops to your agenda!

Shawn Huffman

Sales Manager, Beck Automation

Shawn Huffman has been with Beck Automation for twelve years, serving as the Sales Manager since joining the company. As a customer-focused manager, Shawn assists customers with technical support and the installation of software packages to ensure a service first approach. Beck Automation is a leading control system provider for the metal forming industry making production machines more efficient and profitable.

Brian Rogers, Sr.

Application Manager, FormTek, Inc.

Brian began his experience as a roll form operator and realized he had a great interest in roll form methodology and entered an apprenticeship program to learn troubleshooting and department leadership. During the apprenticeship, his duties included new tooling tryout, troubleshooting of roll form processes, set up, and leadership. Brian became a supervisor with duties including scheduling and troubleshooting of 22 roll mill lines, 25 operators, and set up personnel. He then expanded into tool engineering where he focused on new tooling and continuous improvement projects. Additional duties included new tooling and equipment buy offs. He joined Formtek, Inc. to begin a new chapter in his career as a Senior Applications Engineer. Responsibilities include helping solve customer request using the roll forming process. Brian is a member of and a Past Chair of FMA’s Roll Forming Council.

Andy Allman

President, AMS Controls, Inc.

Andy has been working in the roll forming industry for over 31+ years. Before becoming president, Andy was the VP of engineering at AMS and was heavily involved in the development of high-performance length control systems as well as computer integrated manufacturing software. He has a bachelor’s degree in computer engineering from Mizzou and a master’s in international business from St. Louis University. Andy is a member of the FMA Roll Forming Council.

Steve Ebel

President, Roll Form Solutions

Steve is the President of Roll Form Solutions located in Grand Haven, MI. His initial entry into the roll forming industry began as a machinist making parts for roll formers and presses. From there he worked in the tool room, assembled roll form machines, and put complete roll forming systems together. He has also worked in sales, helping his customers with product development and design, along with quoting roll form tooling and systems. For eleven years, he held the position of Chief Engineer with a large custom roll forming company. In that function, he was responsible for process and product design, tooling quoting, supervision of Tool Engineers, and overseeing the design, build, and purchase of all roll forming tooling and specialized equipment. Steve has a degree in Applied Science Industrial Engineering and over 48 years’ experience in the roll form industry, which enables him to incorporate fundamental principles as well as problem solving techniques to various levels. He is a current member and Past Chair of FMA’s Roll Forming Council.

Matt Werner

Inside Sales Manager, The Bradbury Company

Matt Werner has been with The Bradbury Co., Inc. for 18 years. The first 10 years were in sales and product development with Bradbury’s trim manufacturing line of equipment, which includes hydraulic folders and light gauge slitting equipment. Currently, Matt is the Inside Sales Manager and Director of Marketing for The Bradbury Group of companies, which includes multiple locations around the world. All are involved in the manufacturing of coil processing and roll forming equipment for various industries. Matt is a member of FMA’s Roll Forming Council.